Tree Bark The Definitive Guide to Nature’s Ultimate Protective Barrier, Care & Uses

October 31, 2025

Firestick Remote Blinking Orange? Your Ultimate Troubleshooting Guide & Fixes

November 13, 2025Starting an outdoor project, whether it’s a deck, fence, or raised garden bed, can be exciting, much like a home transformation. But that excitement often turns into confusion once you start looking at lumber options. You want your project to last, to be safe for your family and worth the investment, yet the world of treated lumber can feel like a maze of grades, chemicals, and maintenance rules.

Choosing the wrong type of wood can lead to expensive and frustrating problems, which can derail a home renovation.Rot, insect damage, warping, splintering, or even structural failures are common outcomes when the material isn’t right for the job. Imagine putting in long hours and hard-earned money to build a beautiful deck, only to see it deteriorate after just a few years because the wood wasn’t rated for ground contact or the fasteners corroded. It’s a costly mistake that many homeowners make, simply due to a lack of clear information.

This guide is here to change that. It will help you make sense of treated lumber so you can approach your project with confidence and clarity. You’ll learn how to choose the right type of wood for your needs, understand how treatments affect performance, and take the right steps to ensure long-term durability. With the right knowledge, you can build something that not only looks great but also stands strong for years to come.

Understanding Treated Lumber: The Foundation of Durable Outdoor Projects

What Is Treated Lumber? Your First Line of Defense

Treated lumber is wood that has been infused with chemical preservatives to protect it from decay caused by fungi, insects like termites, and moisture. It’s specifically designed for outdoor use, places where untreated wood would quickly break down due to weather exposure or contact with the ground.

Homeowners and builders use treated lumber because it offers several key benefits:

- Rot Resistance: Untreated wood deteriorates quickly when exposed to moisture or soil. Treated lumber slows this process dramatically.

- Insect Protection: The preservatives safeguard the wood against termites and other wood-boring insects that can silently destroy structures.

- Longer Lifespan: Compared to untreated wood, treated lumber can last many years longer, making it a smarter long-term investment for outdoor projects.

However, one common misconception is that treated lumber is completely immune to damage. It isn’t “rot-proof” or “maintenance-free.” Instead, it’s engineered to delay and reduce decay, provided it’s installed and maintained correctly. Proper care, like sealing exposed cuts and using compatible fasteners, still plays a crucial role in ensuring your project’s durability.

How Lumber Gets Treated: The Science Behind Durability

The strength of treated lumber comes from the way it’s processed. The treatment involves forcing preservatives deep into the wood fibers through a pressure-based system. Here’s how it works:

- Vacuum Stage: Air is first removed from the wood cells inside a sealed cylinder.

- Flooding Stage: The cylinder is then filled with a liquid preservative solution.

- Pressure Stage: High pressure forces the preservative deep into the wood’s cellular structure, ensuring even penetration.

- Final Vacuum: Excess liquid is removed, leaving the wood saturated and ready for drying.

This process transforms ordinary wood into a long-lasting building material capable of withstanding harsh outdoor environments.

Modern Preservatives Explained

Today’s treated lumber uses several types of preservatives, each with its own advantages and best uses:

- ACQ (Alkaline Copper Quaternary): A widely used copper-based treatment that effectively protects against fungi and insects. However, it can be corrosive to standard steel fasteners, so stainless steel or coated hardware is recommended.

- MCA (Micronized Copper Azole): Also copper-based, but the copper is ground into microscopic particles, allowing for better penetration and less corrosion compared to ACQ. It typically gives wood a lighter, more natural look.

- Borate-Treated Lumber: Treated with boron compounds that defend against decay and insects. However, borates are water-soluble, which means this type of lumber shouldn’t be used for direct ground contact or in constantly wet areas. It’s a great choice for interior framing or raised garden beds where leaching could be a concern.

A Brief Historical Note

Before 2003, most residential treated lumber contained CCA (Chromated Copper Arsenate), a preservative that included arsenic. Due to safety concerns, CCA was phased out for residential applications. Modern preservatives like ACQ, MCA, and borates are significantly safer and meet current environmental and building standards.

When evaluating claims about the safety or “toxicity” of treated lumber, always check the latest information from reliable sources such as the EPA or American Wood Protection Association (AWPA).

Expert Tip: Always Check the End Tag

Every piece of treated lumber comes with an end tag. This small but important label provides key information, including:

- The type of preservative used

- The retention level (how much preservative is in the wood)

- The intended use rating, such as above-ground or ground contact

Choosing the right wood for your project depends on reading this tag carefully. Using lumber rated for above-ground use in contact with soil, for example, can lead to early decay and safety issues.

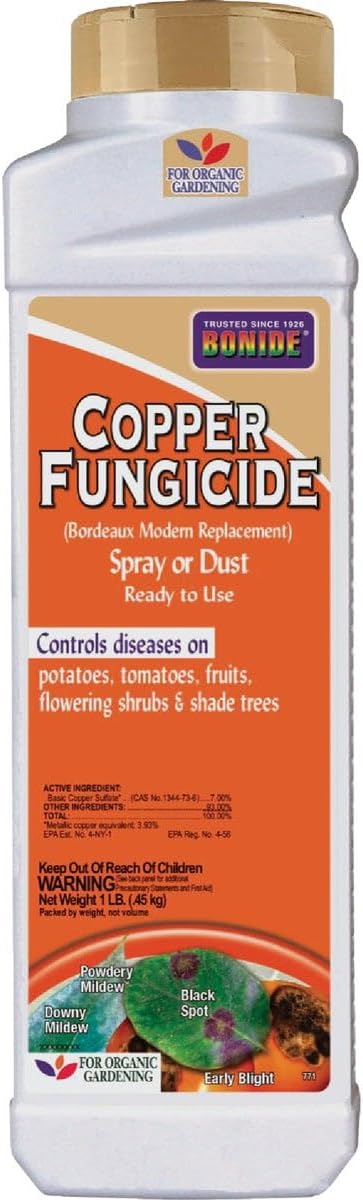

onide Copper Fungicide, 1 lb. Ready-to-Use Spray or Dust for Organic Gardening, Controls Common Diseases in Lawn & Garden

Keep your garden healthy and thriving with Bonide Copper Fungicide, a reliable solution for controlling common plant diseases. This modern Bordeaux mix alternative helps prevent and treat fungal problems like blight, leaf spot, scab, powdery mildew, and peach leaf curl.

Perfect for a wide range of plants, it can be safely applied to fruits, vegetables, beans, flowers, shrubs, and ornamentals. Approved for organic gardening, it’s ideal for those producing organic crops or maintaining chemical-free gardens.

The product arrives ready to use simply apply as a dust or mix with water for a spray application. Follow the label directions for best results and season-long protection.

Key Features:

-

Controls and prevents blight, mildew, scab, and leaf spot

-

Safe for fruits, vegetables, and ornamentals

-

Easy to apply use as dust or spray

-

Approved for organic gardening

-

Effective, modern replacement for traditional Bordeaux mixture

Navigating the Options: Types, Grades, and Selection for Your Project

Decoding Treated Lumber Grades: Above Ground vs. Ground Contact

Not all treated lumber is created equal. Each type is designed for specific conditions, and understanding the grading system helps you choose the right material for your project. Treated lumber is classified by exposure category, which indicates how much preservative the wood retains and how it should be used.

Understanding Exposure Categories

Every piece of treated wood falls into a Use Category (UC) based on its intended exposure to moisture, soil, or water. These categories help determine which lumber is suitable for your specific application:

- Above Ground (UC3A, UC3B):

Used for components that stay mostly dry and are not in contact with soil. Common examples include deck railings, fence pickets, and fascia boards. Because these parts are easier to inspect and maintain, they require less preservative treatment. - Ground Contact (UC4A, UC4B):

Designed for pieces that touch soil or fresh water, or that are difficult to repair or replace, like deck posts, fence posts, and sill plates. These products contain higher preservative levels to withstand constant moisture and decay threats. - Severe Ground Contact (UC4C):

Intended for high-risk structural elements exposed to severe decay conditions. This includes components like foundations or utility poles that require the highest level of protection in non-marine environments. - Marine Grade (UC5A, UC5B, UC5C):

Specially treated for saltwater or brackish water exposure, this category offers the maximum preservative retention. It’s typically used for docks, seawalls, and other coastal structures where decay and corrosion risks are extreme.

Why Retention Levels Matter

The retention level, the amount of preservative in a cubic foot of wood, determines how resistant the lumber is to decay and insects. Higher retention levels mean greater protection and durability.

Choosing the right grade isn’t about going for the “strongest” option available; it’s about matching the wood’s treatment level to your project’s environment. Using ground-contact lumber for above-ground structures adds unnecessary cost, while using above-ground lumber for posts or buried sections can lead to premature failure.

This is where many homeowners get stuck, confused by the codes and categories printed on tags. The good news? Once you know what to look for, it’s simple.

How to Identify the Right Grade

Every piece of treated lumber includes an end tag, typically stapled to the board. This small tag provides all the essential information you need:

- The preservative type (e.g., ACQ, MCA, or Borate)

- The retention level

- The Use Category (e.g., Above Ground or Ground Contact)

If your project involves posts, retaining walls, or anything that touches the ground, make sure the tag reads “GROUND CONTACT.” For railings, trim, or decking above the soil line, “ABOVE GROUND” will suffice.

Expert Tip: Match the Retention to the Risk

The key to project longevity is balance. Use higher retention levels only when exposure justifies it, such as direct ground burial or freshwater immersion. For lighter-duty, above-ground applications, a lower level of treatment will still offer excellent performance without unnecessary expense.

Treated Lumber Selection Guide: Choosing the Right Wood for the Job

Choosing the right lumber for your outdoor project is all about balance between performance, cost, and environmental responsibility. The chart below offers a practical comparison of common lumber types, helping you make an informed choice based on where and how the wood will be used.

|

Lumber Type |

Primary Preservative |

Typical Uses |

Pros |

Cons |

Estimated Cost/LF |

Environmental Note |

|

ACQ Treated |

ACQ (Alkaline Copper Quaternary) |

Decks, fences, structural posts, and other ground-contact applications |

Excellent resistance to rot and insects; widely available and proven for outdoor use |

Can corrode standard steel fasteners; may warp or check over time if not sealed properly |

~$2.00 – $4.00 |

Some copper leaching, but significantly safer and less toxic than older CCA-treated wood |

|

MCA Treated |

MCA (Micronized Copper Azole) |

Decks, fences, pergolas, and general outdoor framing |

Good rot and insect resistance; less corrosive than ACQ; lighter color offers a more natural look |

Still needs corrosion-resistant fasteners; slightly more expensive than ACQ |

~$2.50 – $4.50 |

Reduced copper leaching due to micronized particles; environmentally safer choice |

|

Borate Treated |

Borate (Boron compounds) |

Interior framing, sill plates, raised beds, and above-ground decking (must be protected from moisture) |

Non-corrosive; low toxicity; highly effective against termites and other insects |

Not suitable for ground contact or wet conditions, borate washes out easily |

~$1.80 – $3.50 |

Low environmental impact; often used for eco-conscious builds and garden applications |

|

Untreated Wood (e.g., Pine) |

None |

Indoor framing or temporary outdoor projects |

Affordable and easy to work with |

No protection from moisture or insects; very short lifespan outdoors |

~$1.00 – $2.50 |

Fully natural, but frequent replacement increases long-term waste and cost |

|

Composite Decking |

Recycled plastics and wood fibers |

Decking, railings, trim, and decorative outdoor structures |

Extremely low maintenance; durable; splinter-free; available in many colors |

Higher upfront cost; surface can heat up in full sun; minor fading over time |

~$5.00 – $10.00 |

Made from recycled materials; very long lifespan with minimal environmental impact. |

Quick Takeaways

- For structural use (like posts or beams touching soil), ACQ or MCA-treated lumber is the safest choice.

- For above-ground or interior framing, borate-treated wood protects with minimal environmental impact.

- For long-term, low-maintenance decking, composite materials may cost more upfront but save effort and money over time.

Expert Tip: Check Local Availability and Regulations

Prices can vary based on region, lumber grade, and current market demand. Always verify local availability and building code requirements before purchase. Some areas may have restrictions or preferred treatments for environmental reasons.

Project Planning & Application: Where and How to Use Treated Lumber

Choosing the right type of treated lumber is only half the job; knowing where and how to use it ensures your project lasts. Each application has different exposure levels, so selecting the correct grade and fasteners makes all the difference in performance and longevity.

Common Uses & Ideal Applications

Decks and Patios

Treated lumber is the backbone of most deck structures. Posts, beams, and joists that touch or sit close to the ground should always be Ground Contact grade to resist rot and moisture. For decking boards, above-ground grade lumber works well, though many homeowners now prefer composite materials for their low maintenance and appearance.

Fences

Fence longevity depends heavily on using the right lumber in the right place. Fence posts should always be Ground Contact grade, as they’re buried and constantly exposed to moisture. Rails and pickets can typically use above-ground grade, which still offers protection against weather and insects.

Pergolas and Gazebos

These outdoor structures benefit from treated supports and beams, especially where wood is exposed to rain or soil. Using treated lumber here ensures the structure stays sturdy and attractive for years with minimal maintenance.

Raised Garden Beds

This is a frequent area of concern. When growing edible plants, you want materials that are safe for soil contact.

- Best Options: Naturally rot-resistant woods like cedar or redwood, borate-treated lumber, or composite boards.

- If using copper-based treated lumber (ACQ or MCA): Line the interior with a thick, non-permeable plastic barrier to prevent the soil from touching the treated surface directly.

Expert Tip: For raised beds used to grow vegetables or herbs, stick to untreated cedar, redwood, or borate-treated lumber rated for contact with edible plants. If you use copper-treated lumber, always add a plastic liner to prevent leaching into the soil.

Sheds and Outbuildings

Treated lumber is ideal for skids, floor joists, and bottom plates that rest near or on the ground. These components are highly vulnerable to moisture wicking from the soil, and treated wood provides essential protection.

Play Structures

For swing sets, climbing frames, and other outdoor play areas, treated posts and supports ensure safety and durability. They resist decay and insect damage, keeping structures stable and reducing maintenance needs over time.

Fasteners and Hardware: Compatibility Is Key

Even the best lumber won’t last if paired with the wrong hardware. The chemicals in modern treated wood, especially copper-based formulas like ACQ and MCA, are corrosive to standard steel and lightly galvanized fasteners. Using incompatible screws or nails can cause rapid rust, weakened joints, and even structural failure over time.

Recommended Corrosion-Resistant Fasteners

- Hot-Dipped Galvanized (HDG):

Choose fasteners that meet ASTM A153 standards. The thick zinc coating provides excellent resistance to corrosion. - Stainless Steel:

Grades 304 or 316 are the best options for high-moisture or coastal areas. They’re more expensive but offer unmatched longevity and protection. - Specialty Coated Screws:

Many manufacturers produce fasteners specifically labeled “ACQ Compatible” or “For Treated Wood.” Always double-check packaging or manufacturer specs before purchase.

Expert Tip: Never use standard galvanized or uncoated fasteners with treated lumber. Instead, choose hot-dipped galvanized, stainless steel, or ACQ-compatible coated fasteners to prevent corrosion and ensure long-term strength.

Product Recommendation:

For any outdoor project using treated lumber, always use corrosion-resistant fasteners; they’re a small upfront investment that protects your entire build.

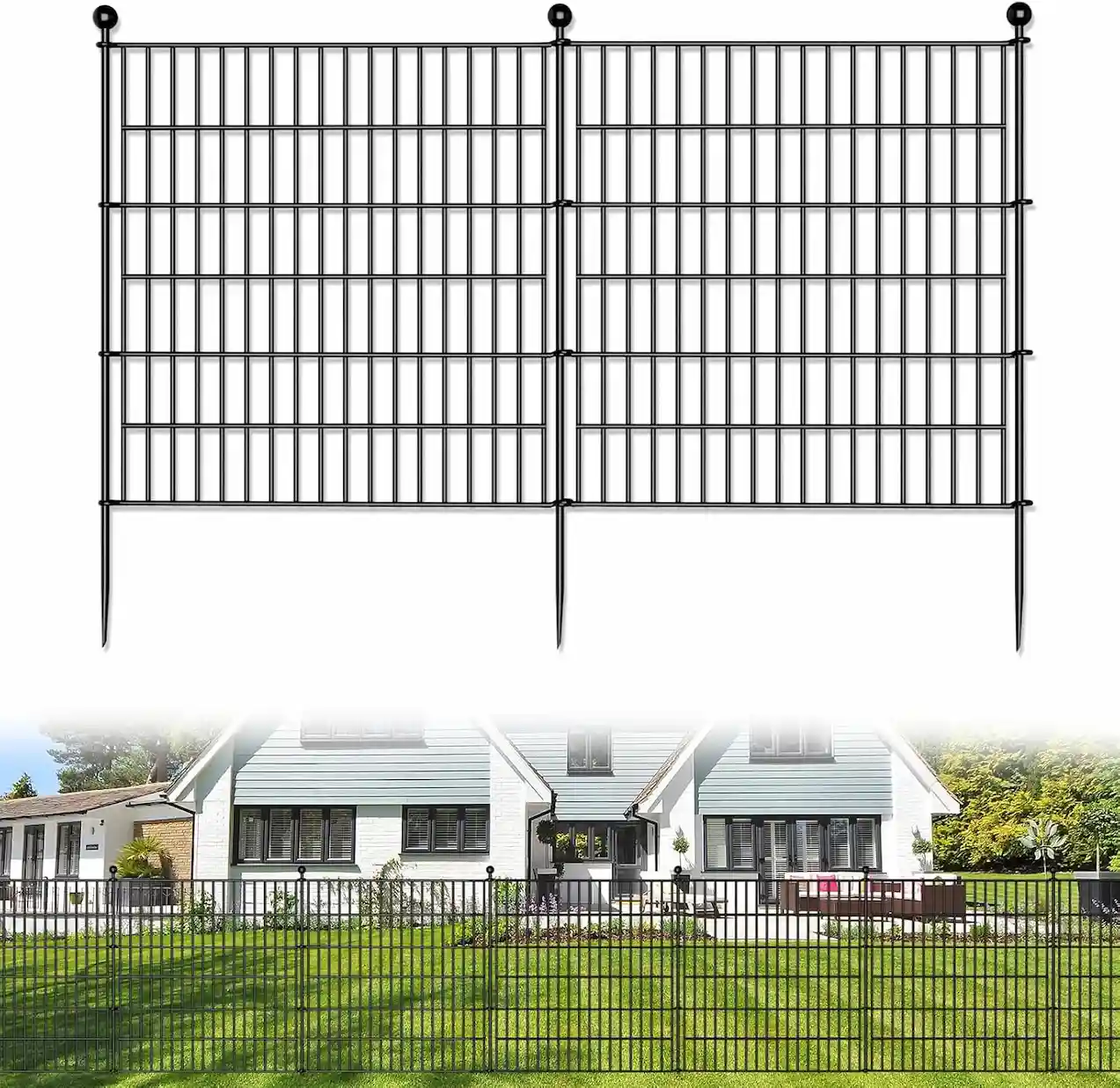

10 Panels No Dig Decorative Outdoor Garden Fence for Yard, 32 in(H) X 23.6 ft(L) Animal Barrier Fencing Rustproof Metal Wire Panel Border for Dog, Rabbits, and Patio Temporary Ground Stakes

Enhance your garden’s beauty and security with this high-quality wrought iron garden fence, designed for both function and style. Built from durable, rustproof metal, it offers long-lasting performance without the maintenance required by wooden fencing no rotting, warping, or fading, just reliable protection season after season.

Installation is quick and easy with the no-dig design. Each pre-assembled panel anchors securely into the ground using sturdy stakes no special tools or complicated setup needed.

This secure and sturdy barrier effectively keeps pets and small animals out while withstanding harsh outdoor conditions. The classic spear-top pickets provide both protection and timeless elegance, making it ideal for garden borders, patios, pathways, or play areas.

Flexible and customizable, the panels connect easily to fit any layout or extend coverage as needed, offering a versatile fencing solution for any outdoor space.

CROWN SHADES 13x13 Pop Up Gazebo, Canopy Tent, Gazebos on Clearance - Outdoor Gazebo for Backyard & Patio Furniture

Enjoy instant shade and comfort anywhere with the CROWN SHADES 10x10 Pop-Up Canopy, designed for effortless setup and all-day outdoor protection. Featuring patented one-push center lock technology, this canopy opens and secures all four legs in seconds no tools, no hassle.

With a 13' x 13' top and 169 sq. ft. of shade, it’s perfect for backyards, patios, camping, and outdoor events. The rugged 150D silver-coated fabric offers UPF 50+ UV protection, is water-repellent, and includes waterproof sealing tape to prevent pooling. The removable mesh netting provides extra protection from insects while allowing airflow and visibility.

Built for stability, the canopy’s high-grade steel frame with hardened bolts supports up to 120 lbs distributed weight, ensuring reliable performance. Despite its strength, setup and storage are effortless with the included Sto 'N Go carry bag, stakes, guy ropes, weight bags, and removable nettings.

Safety, Maintenance & Longevity: Maximizing Your Investment

Building with treated lumber offers durability and value, but long-term performance depends on how safely you handle it and how well you maintain it. By following the right safety practices and ongoing care routines, you’ll protect your health, your project, and your investment.

Essential Safety Precautions When Working with Treated Lumber

A common pain point for many DIYers and homeowners is the lack of clear guidance on how to handle, cut, and dispose of treated wood safely. While modern treatments are much safer than older arsenic-based formulas, proper precautions are still essential.

Personal Protective Equipment (PPE)

- Gloves: Always wear gloves to prevent skin contact with wood preservatives.

- Eye Protection: Safety glasses protect against sawdust, splinters, and flying debris when cutting or drilling.

- Dust Mask or Respirator: Use a certified dust mask or respirator when cutting, drilling, or sanding treated wood to avoid inhaling fine dust particles that may contain chemical preservatives.

Expert Tip: Always wear gloves, eye protection, and a dust mask when working with treated lumber. It’s a simple step that prevents irritation and reduces health risks.

Ventilation Matters

Work outdoors or in a well-ventilated area. Proper airflow minimizes exposure to sawdust and chemical fumes, especially during cutting or sanding, enhancing your indoor air quality.

Handling Sawdust and Scraps

Collect all sawdust and offcuts for safe disposal. Never use treated lumber waste as mulch, compost, or animal bedding, especially near edible plants.

Hygiene Practices

After handling treated wood, wash your hands thoroughly with soap and water before eating, drinking, or touching your face.

Food Contact Warning

Avoid using treated lumber for food preparation surfaces like countertops or cutting boards. It’s best reserved for structural and outdoor applications only.

E-E-A-T Note:

It’s important to separate myth from fact. While today’s treated lumber is much safer than the older CCA-treated wood, it still contains active preservatives. Safe handling isn’t about fear; it’s about smart practice and awareness.

Maintenance for Lasting Beauty and Durability

Treated lumber is built to resist rot and insects, but that doesn’t make it immune to weathering, fading, or surface damage. Proper maintenance ensures your deck, fence, or outdoor structure stays strong and attractive for years.

Acclimation

Most treated lumber arrives moist from the pressure treatment process. Before building, let it sit and acclimate to your local climate for a few weeks. This allows moisture levels to stabilize, reducing warping, twisting, and shrinkage once installed.

Expert Tip: Let your lumber dry out before construction. This step alone prevents many common post-installation issues like bowing or splitting.

Sealing and Staining

Why It Matters:

While preservatives protect from biological decay, they don’t block UV rays, rain, or surface moisture. Over time, untreated surfaces can gray, crack, or warp. Applying a sealer or stain preserves both appearance and structure.

When to Apply:

Wait about 3–6 months after installation, allowing the wood to dry fully before sealing. Test by sprinkling water on the surface. If it beads, wait a little longer; if it absorbs, the wood is ready.

Choosing the Right Product:

Look for exterior-grade sealers or stains specifically formulated for treated wood. These products enhance color, repel moisture, and protect against UV damage.

Expert Tip: A quality wood sealer or stain applied within the first few months extends your deck or fence’s life dramatically. Reapply every 2–3 years for continued protection.

Product Recommendation:

Use a wood sealer or stain designed for treated lumber. It’s one of the best investments you can make for long-term durability and appearance.

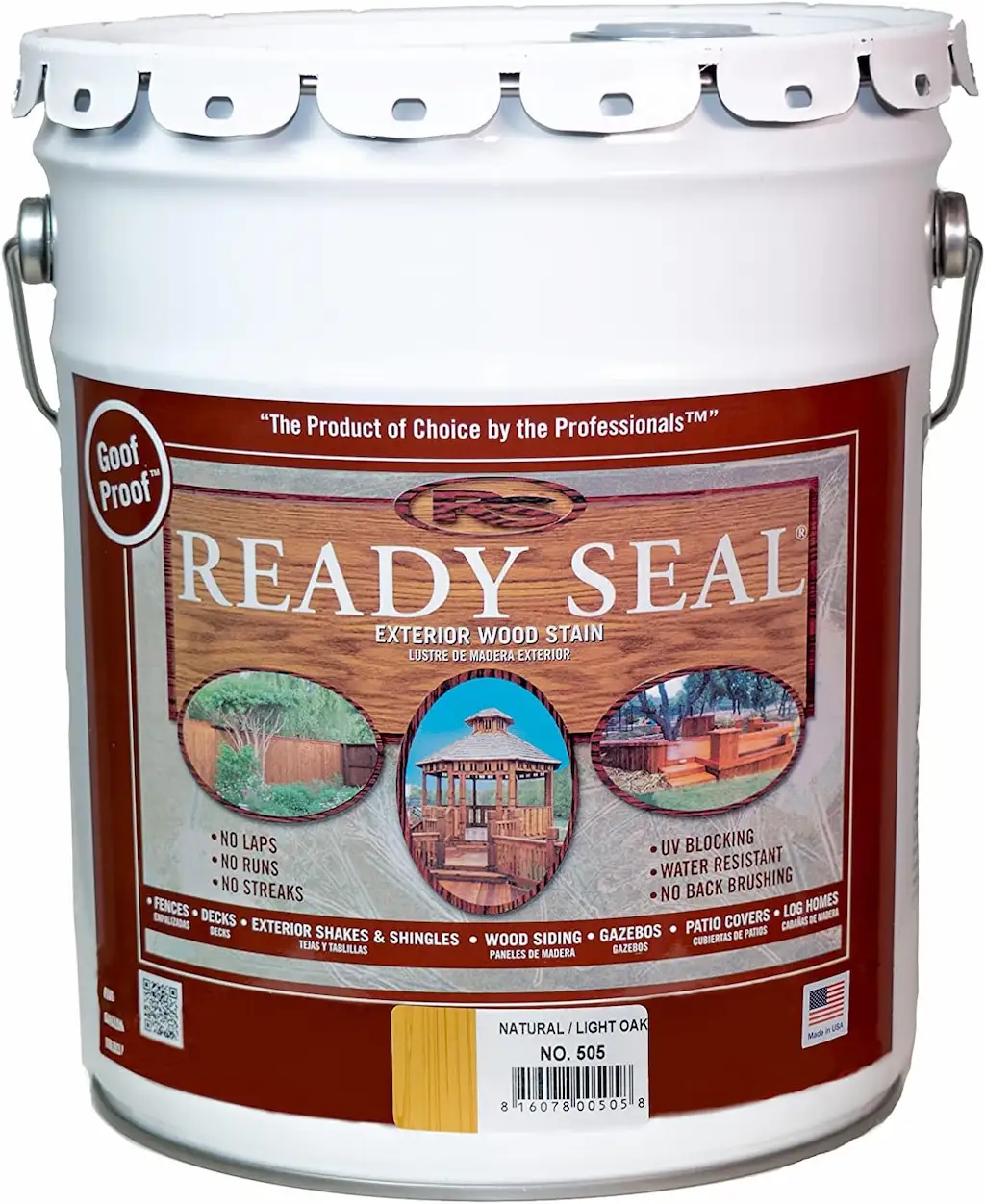

Ready Seal 505 Exterior Stain and Sealer for Wood, 5-Gallon, Light Oak

Protect and enhance your outdoor wood surfaces with Ready Seal 505 Light Oak Exterior Stain and Sealer, the ultimate all-in-one solution for natural beauty and lasting durability. This oil-based, semi-transparent stain penetrates deeply to highlight the wood’s grain and texture while providing long-term protection against mold, mildew, and UV damage.

Perfect for decks, fences, siding, and outdoor furniture, Ready Seal’s “Goof Proof” formula makes application effortless no primer, no back brushing, and no risk of streaks or lap marks. Whether applied with a brush, roller, or sprayer, it blends seamlessly for a professional finish every time.

Unlike other stains, Ready Seal requires no sanding, stripping, or thinning between applications, ensuring easy maintenance and consistent color over time. The product reaches its true Light Oak color within 14 days of application, gradually revealing a rich, natural finish.

Key Features:

-

2-in-1 Stain & Sealer: Deep-penetrating oil formula enhances wood grain and texture.

-

No Primer or Back Brushing: Self-blending design for streak-free results.

-

True Color in 14 Days: Achieves its natural tone after full absorption.

-

Easy Application: Apply with sprayer, roller, or brush no dilution needed.

-

Low Maintenance: Reapply anytime without sanding or stripping.

-

Weather-Resistant Protection: Guards wood against UV rays, mold, and mildew.

Cleaning and Regular Care

Treated lumber benefits from routine cleaning. Dirt, mildew, and algae can accumulate, especially in shaded or damp areas.

- Use a pressure washer on a low setting or a stiff brush with mild detergent to remove buildup.

- Rinse thoroughly and let the wood dry completely before resealing or staining.

Product Recommendation: A pressure washer is effective for cleaning, but use it gently to avoid damaging the wood surface.

Common Issues and How to Prevent Them

- Warping, Twisting, and Checking: These are natural as wood dries. Minimize them by allowing acclimation, sealing the wood, and fastening boards securely.

- Expansion and Contraction: Wood moves with changes in humidity. Leave small gaps between decking boards to allow natural expansion and drainage.

- Poor Ventilation: Even ground-contact-rated lumber benefits from airflow. Avoid sealing off moisture beneath decks or around posts; ventilation helps prevent premature decay and mold growth.

Expert Tip: Design your project with airflow in mind. Good ventilation is one of the simplest ways to keep moisture from causing hidden damage.

Westinghouse Short Pressure Washer Gun - 3600 Max PSI, M22 Connector - for Gas and Electric Pressure Washers

Transform your cleaning routine with the Westinghouse Short Pressure Washer Gun, a compact yet powerful tool built for versatility and control. Designed for homeowners, DIYers, and auto-detailing enthusiasts, this pressure washer attachment delivers up to 3600 PSI of high-performance cleaning for vehicles, driveways, decks, and outdoor furniture.

With its universal M22-14mm inlet and 1/4” quick-connect female outlet, this short gun offers plug-and-play compatibility with most major pressure washer brands no extra adapters or washers required. Lightweight and ergonomically designed, it fits comfortably in one hand, reducing fatigue and providing greater maneu verability for tight spaces or long cleaning sessions.

Pair it with a Westinghouse Foam Cannon for a professional-level soap application and spotless finish every time. Built tough to withstand heavy-duty use, it’s your go-to tool for achieving pristine results without the bulk of a full-length wand.

Environmental Impact & Responsible Practices

As awareness of sustainability grows, more homeowners and builders are asking smart questions about the environmental footprint of treated lumber. Concerns about chemical preservatives, soil impact, and responsible disposal are valid, and the good news is that modern treatment methods have evolved significantly. Today’s treated wood is safer, longer-lasting, and more environmentally responsible than ever before.

Environmental Considerations & Responsible Disposal

A common concern among DIYers and professionals alike is understanding how treated lumber affects the environment. From the chemicals used in preservation to proper disposal methods, every step matters in reducing environmental impact.

Treated Lumber for the Modern Eco-Conscious DIYer

Modern treated lumber is the result of years of innovation aimed at balancing durability with environmental responsibility. The preservatives used today are designed to minimize leaching, reduce toxicity, and extend the life of wood products, meaning fewer replacements and less waste over time.

Environmental Impact of Preservatives

- Modern Formulations: Preservatives such as Micronized Copper Azole (MCA) have largely replaced older, more aggressive compounds. MCA is designed to reduce copper leaching into the soil, making it a more sustainable option for outdoor use.

- Borate Treatments: Derived from naturally occurring minerals, borate-based treatments are effective against insects and decay while maintaining a lower environmental impact. Their one limitation is solubility, which makes them less suitable for high-moisture or ground-contact applications.

These improvements show how far the industry has come in aligning structural integrity with ecological awareness.

Responsible Disposal Methods

Disposing of treated wood properly is just as important as using it responsibly. Improper disposal can release harmful substances into the air or soil.

Never Burn Treated Lumber

Burning treated lumber is a serious health and environmental hazard. When exposed to high heat, preservatives release toxic fumes and heavy metal residues that can contaminate the air and nearby soil.

Expert Tip: Never burn treated lumber. Instead, take leftover materials, sawdust, and scrap wood to a designated hazardous waste facility or recycling center approved for treated wood disposal.

Follow Local Regulations

Every region has its own waste management policies. Before disposing of treated lumber, contact your local recycling or waste authority for guidance. Many areas classify treated wood as controlled or hazardous waste, meaning it cannot be landfilled with regular debris.

By following local rules, you not only protect your community’s environment but also comply with safety standards set by environmental agencies.

Eco-Friendly Alternatives

While treated lumber remains a reliable choice for strength and longevity, eco-friendly materials are gaining popularity among builders who want sustainable options without compromising performance.

- Naturally Durable Woods: Species such as cedar, redwood, and black locust have natural oils and tannins that resist rot and insects. Though more expensive, they require fewer chemical treatments and offer a beautiful, organic finish.

- Composite Decking: Made from recycled plastics and wood fibers, composite boards are extremely durable, resistant to moisture, and virtually maintenance-free. They’re ideal for homeowners seeking long-term sustainability with minimal upkeep.

- Thermally Modified Wood: This process involves heating wood to high temperatures, changing its cellular structure to resist rot and warping, without any chemicals. It provides a natural, eco-friendly alternative to traditional pressure-treated lumber.

- Steel or Aluminum Framing: For structural components like deck subframes, these metals are corrosion-resistant, long-lasting, and 100% recyclable, making them a responsible choice for modern outdoor builds.

Exploring these alternatives allows builders to match material selection with environmental goals and personal preferences.

Building with Environmental Awareness

Being environmentally responsible doesn’t mean avoiding treated lumber altogether; it means using it wisely. Modern preservatives are safer, and when combined with proper installation and disposal practices, they provide decades of reliable use with minimal ecological impact.

Whenever possible, choose FSC-certified lumber (Forest Stewardship Council) to ensure the wood comes from responsibly managed forests. For disposal and recycling, always refer to local or national environmental protection guidelines to stay compliant and safe.

Frequently Asked Questions (FAQs) About Treated Lumber

Conclusion: Build with Confidence

Choosing the right treated lumber isn’t just about picking a type of wood; it’s about making smart, informed decisions that protect your investment for years to come. When you match the grade to your project’s exposure, use the right hardware, and follow safe handling practices, you set the foundation for outdoor structures that stand strong through every season.

Key Takeaways for Your Next Project

- Match Grade to Project: Select the correct treated lumber grade (Above Ground, Ground Contact, etc.) based on your project’s exposure level to ensure maximum durability and safety.

- Fastener Compatibility is Non-Negotiable: Always use hot-dipped galvanized or stainless steel fasteners. They’re essential for preventing corrosion and maintaining structural integrity.

- Prioritize Safety: Wear gloves, eye protection, and a dust mask when cutting or drilling. Work in well-ventilated spaces and dispose of scraps responsibly; never burn treated wood.

- Maintain for Longevity: Allow lumber to acclimate before building, then seal or stain it to protect against weathering. Regular cleaning helps prevent mold and keeps your project looking its best.

Finally, treated lumber technology and standards continue to evolve. Check for the latest updates and recommendations from trusted sources to make sure your next outdoor build is safe, durable, and environmentally responsible. With the right knowledge and materials, you can build confidently, knowing your effort and investment will last for decades.